Posted At: May 08, 2025 - 2,235 Views

What Is a Wet Seal?

In industrial settings, preventing fluid leakage in rotating equipment like pumps and compressors is crucial. One effective solution employed is the wet seal. But what is a wet seal, and why is it essential in various applications? This guide delves into the fundamentals of wet seals, their operation, advantages, and how they differ from dry seals.

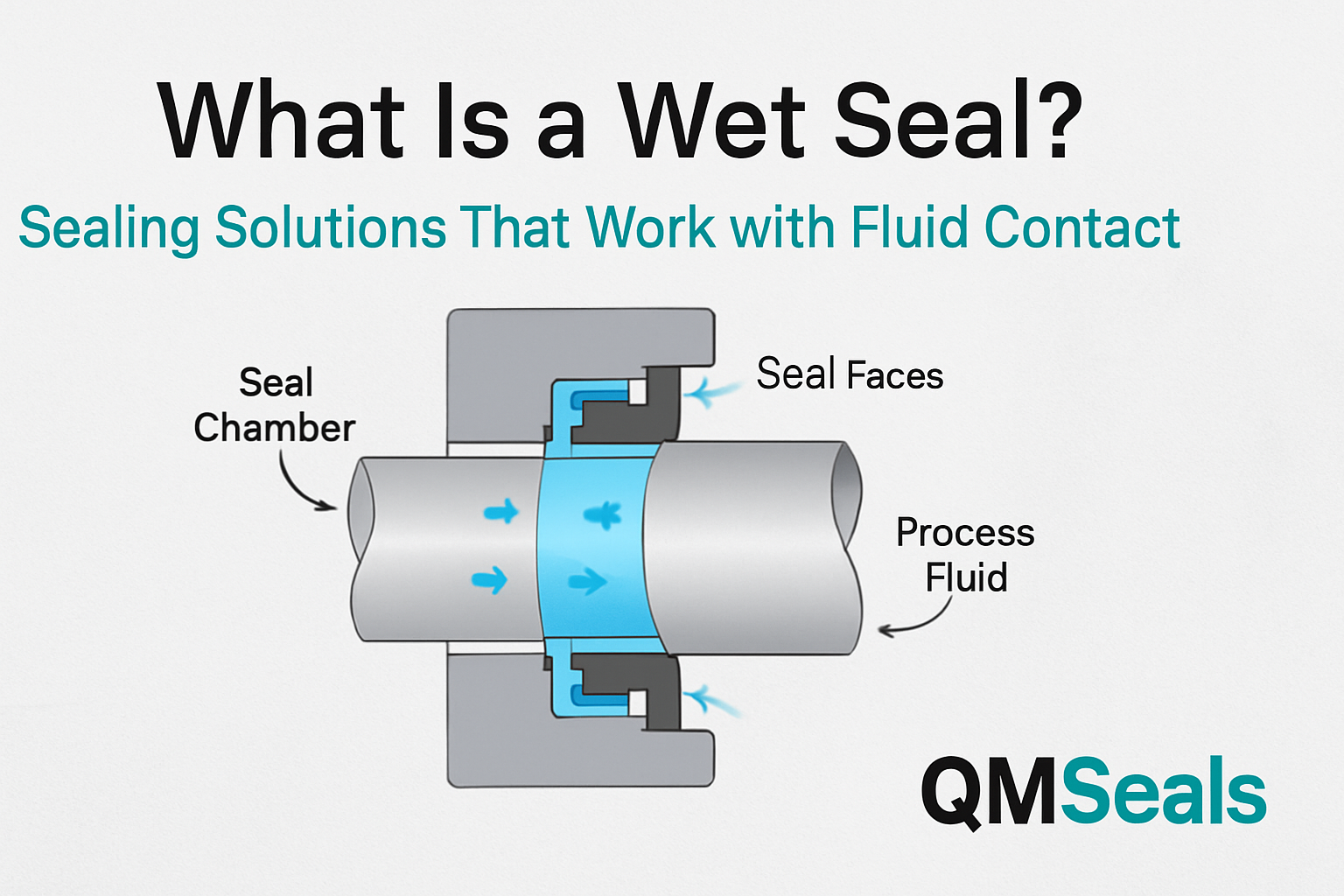

Understanding Wet Seals

A wet seal is a type of mechanical seal that utilizes a liquid—often oil or water-based—to create a barrier between rotating and stationary components in machinery. This liquid serves multiple purposes:

Lubrication: Reduces friction between seal faces.

Cooling: Dissipates heat generated during operation.

Sealing: Prevents the escape of process fluids.

By maintaining a thin film of liquid between the seal faces, wet seals ensure efficient operation and longevity of equipment.

How Wet Seals Work

Wet seals function by introducing a lubricating fluid between the rotating shaft and the stationary housing of equipment. This fluid forms a film that:

Lubricates the seal faces, minimizing wear.

Cools the contact surfaces, preventing overheating.

Seals the interface, reducing or eliminating leakage.

The effectiveness of a wet seal depends on maintaining the appropriate pressure and cleanliness of the lubricating fluid.

Applications of Wet Seals

Wet seals are commonly used in industries where equipment handles liquids under varying pressures and temperatures. Typical applications include:

- Chemical processing plants

- Water and wastewater treatment facilities

- Oil and gas industries

- Pharmaceutical manufacturing

- Food and beverage production

Their ability to handle a range of fluids makes wet seals versatile for numerous industrial processes.

Advantages of Wet Seals

- Implementing wet seals in machinery offers several benefits:

- Enhanced Sealing Efficiency: Effective in preventing fluid leakage.

- Extended Equipment Life: Reduced friction leads to less wear and tear.

- Versatility: Suitable for various fluids and operating conditions.

- Cost-Effective Maintenance: Properly maintained wet seals can reduce downtime and repair costs.

Wet Seals vs. Dry Seals

Understanding the distinction between wet and dry seals is essential for selecting the appropriate sealing solution.

Feature | Wet Seal | Dry Seal |

|---|---|---|

| Lubrication | Requires liquid lubrication | Operates without liquid; uses gas or air |

| Maintenance | Regular fluid checks and replacements needed | Lower maintenance due to non-contact operation |

| Leakage Risk | Potential for fluid leakage if not maintained | Minimal leakage; suitable for hazardous gases |

| Application | Ideal for liquid-handling equipment | Preferred for gas compressors and turbines |

Maintenance Tips for Wet Seals

To ensure optimal performance of wet seals:

Regular Inspections: Check for signs of wear or leakage.

Fluid Quality: Maintain the cleanliness and appropriate pressure of the lubricating fluid.

Proper Installation: Ensure seals are correctly fitted to prevent misalignment.

Monitor Operating Conditions: Keep an eye on temperature and pressure to avoid exceeding seal specifications.

Adhering to these maintenance practices can significantly extend the life of wet seals and the equipment they protect.

Conclusion

A wet seal plays a vital role in maintaining the integrity and efficiency of industrial machinery by preventing fluid leakage and reducing wear. Understanding what a wet seal is, how it operates, and its advantages over other sealing methods is crucial for engineers and maintenance professionals. By selecting the appropriate seal type and adhering to proper maintenance protocols, industries can ensure the longevity and reliability of their equipment.

Frequently Asked Questions

What is a wet seal?

A wet seal is a method of sealing joints or gaps using a liquid or fluid barrier, commonly applied in construction, mechanical systems, and waterproofing to prevent leaks and ensure durability.

Where are wet seals commonly used?

Wet seals are widely used in building construction (such as window and façade sealing), mechanical engineering (for pumps and rotating equipment), and waterproofing applications in bathrooms, balconies, and decks.

How does a wet seal differ from a dry seal?

A wet seal uses a liquid or gel-like material to create a flexible, watertight barrier, while a dry seal typically relies on pre-formed gaskets or strips that do not require curing or fluid application.

What are the main benefits of using a wet seal?

Wet seals provide excellent leak prevention, flexibility to accommodate movement, and long-lasting protection against water or fluid intrusion, making them ideal for both remedial repairs and new installations.

Can wet seals be used for both residential and industrial purposes?

Yes, wet seals are suitable for a wide range of applications, from residential waterproofing (like bathrooms and balconies) to industrial settings involving pumps, compressors, and other rotating equipment.