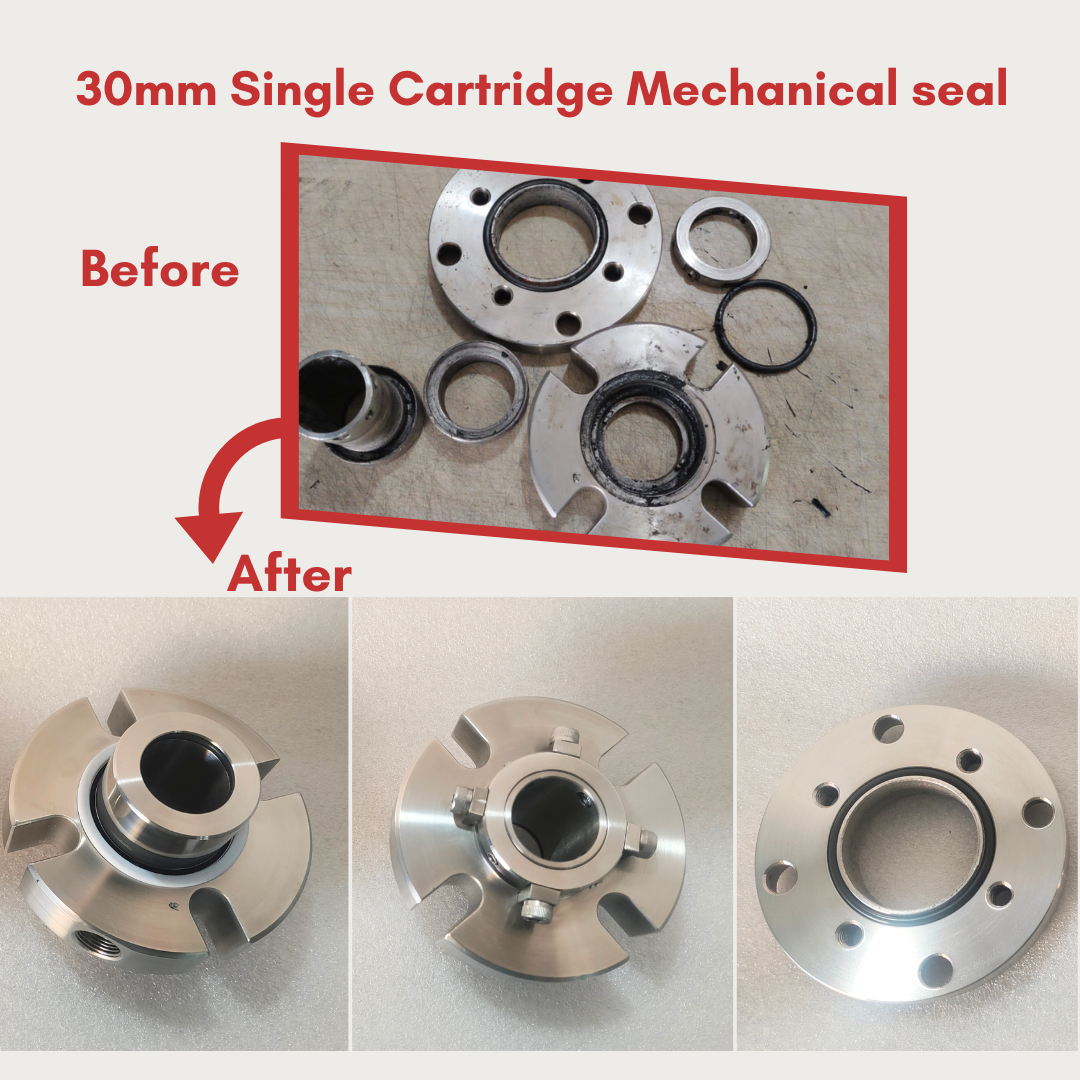

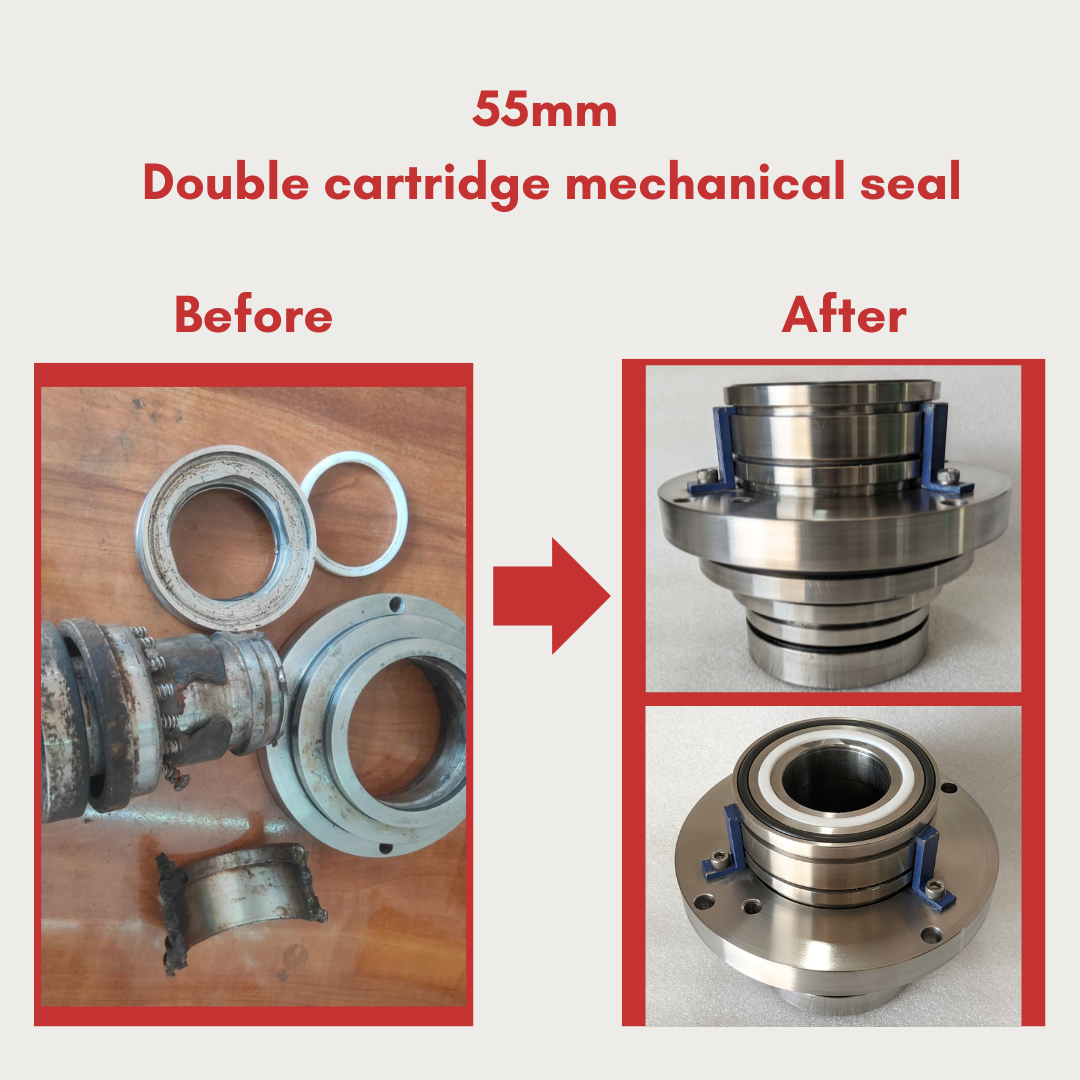

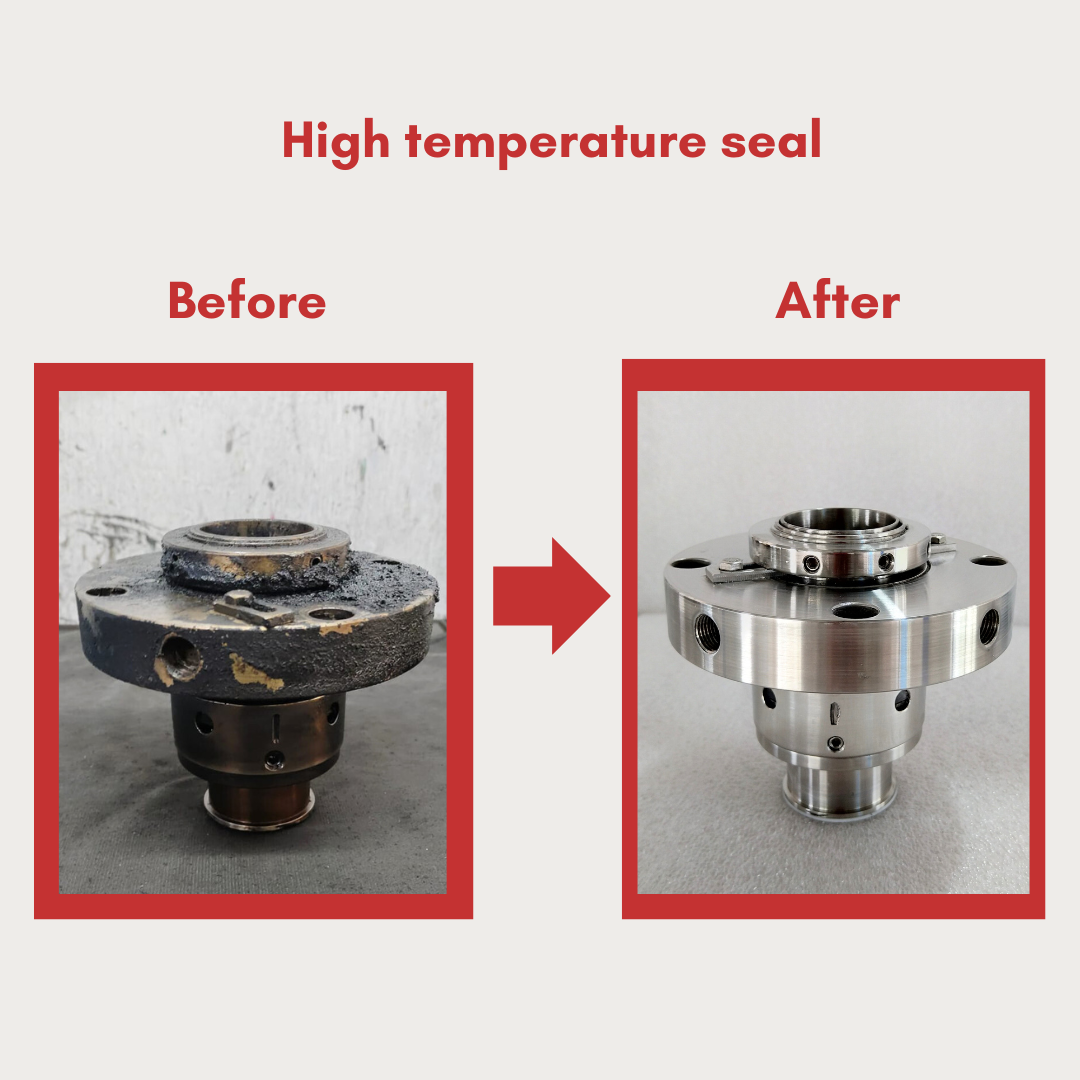

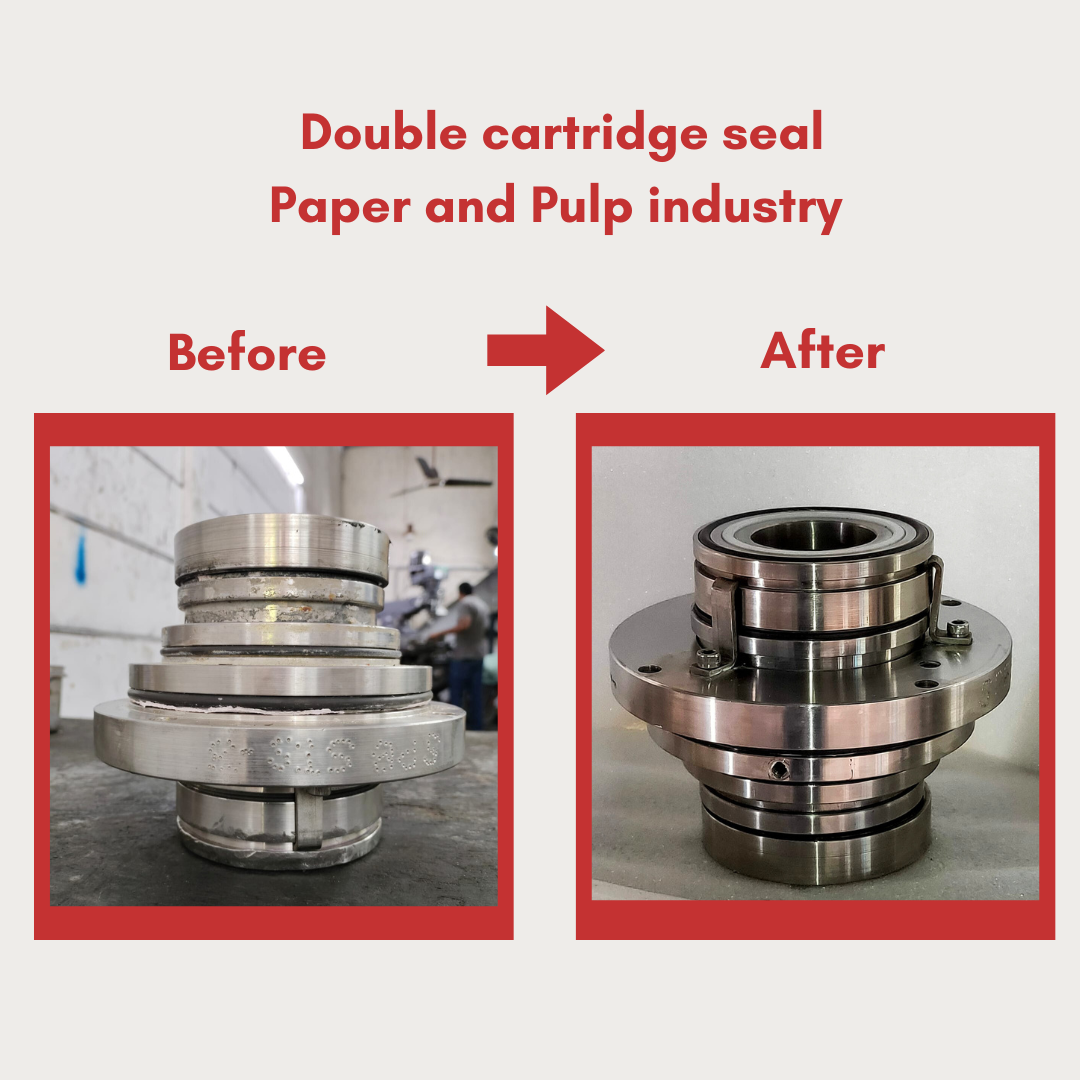

Mechanical seal repair service

Here at QMseals, we want to help you save money any way that we can.

We provide refurbishment service for all types of seals, with the option to save money rather than purchase a new one. This cost-effective solution decreases the price by 40%. We provide refurbishment service of all seals including single spring, multi spring, cartridge, bellow seals, agitator seals, etc., including those manufactured by competitors. Our team of experts can have your seal up and running again in no time.

Terms and Benefits

We provide new seal guarantee options for refurbished seals to ensure that you're getting the best service.

Refurbishing your old seal includes mandatory change of springs, elastomers, and screws.

The seal phases, the gland plate and the flange for cartridge assembly are all reusable, and usually only need to be changed only if they're broken. If necessary modifications are made, they can be used again. We help you minimize the cost in the best way possible.

Reporting on conditions and analysing seal failures for proof of any possible issues in processes or equipment.

In case of need, technical enhancements may involve the reworking the design and enhancement of materials used in O-rings.

Replacement hard faces in Ceramic, Tungsten Carbide and Silicon Carbide

Our facility offers Diamond lapping services that allow for precision lapping of surfaces with an accuracy of up to 2 helium light bands.

Provision of wear-parts and bespoke components in exotic alloys such as Alloy 20, Alloy 276, Titanium, Ferralium, Inconel and more

Diamond grinding facilities for hard face materials.

Specialist coating service including Chrome-Oxide, HVOF and stainless steels

Manufacture of PTFE components in variants such as pure, glass-filled and carbon-filled

Once refurbished, the seal is subjected to a series of tests such as pressure tests and other assessments following specific protocols to guarantee that any leakage issues are resolved.