Posted At: Apr 18, 2025 - 746 Views

What Are Spring Energized Seals?

When it comes to sealing in demanding environments—extreme temperatures, high pressures, or aggressive chemicals—spring-energized seals stand out as the go-to solution. Engineered for durability and reliability, these advanced sealing solutions excel in harsh environments where other seals may fail. But what exactly are spring-energized seals, and why are they used so widely in industries like aerospace, oil and gas, and pharmaceuticals? Let’s break it down.

Understanding Spring Energized Seals

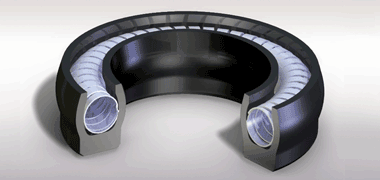

A spring-energized seal works by merging a resilient plastic material—like PTFE—with a metal spring, creating consistent sealing pressure to prevent leaks under fluctuating conditions.

The seal lip is energized by a metallic spring—often made from stainless steel or other corrosion-resistant alloys—that applies continuous pressure, ensuring consistent sealing even as the sealing surfaces wear down or face pressure fluctuations.

Why Use Spring-Energized Seals?

Spring-energized seals offer several advantages over traditional O-rings, lip seals, or rubber seals:

Wide Temperature Range: With the right material selection, these seals can function in temperatures ranging from cryogenic (-200°C) to extremely high heat (up to 300°C).

Chemical Resistance: PTFE-based seals are resistant to most chemicals, making them ideal for aggressive media.

Low Friction: They operate with exceptionally low friction, minimizing wear on components and boosting the overall longevity of the sealing system.

Pressure Resistance: Spring-energized designs can handle both vacuum and high-pressure sealing requirements.

Self-compensating Design: As the sealing surface wears or pressure changes, the spring compensates to maintain contact, ensuring a leak-free seal.

Types of Spring Energized Seals

Here are the most common configurations:

1. U-Cup Seals

U-cup designs are ideal for dynamic sealing applications where low friction and high wear resistance are needed. They’re commonly used in rotary shaft sealing solutions.

2. Cantilever Spring Seals

These are ideal for low-pressure applications and provide excellent performance in cryogenic conditions.

3. Helical Spring Seals

Often used in high-pressure environments, these provide greater force over a wider deflection range.

Applications of Spring Energized Seals

These seals are a popular choice in industries where reliability and chemical resistance are non-negotiable:

Aerospace: For fuel and hydraulic systems.

Oil & Gas: For high-pressure pumps and valves.

Medical Devices: Ensuring contamination-free environments.

Chemical Processing: Withstanding corrosive fluids and extreme conditions.

Cryogenic Systems: Maintaining a reliable seal at ultra-low temperatures.

Material Options for Seal Jackets

Spring-energized seals can be customized with various materials based on the application's needs. Common options include:

PTFE (Polytetrafluoroethylene) is prized for its outstanding resistance to chemicals and its ability to operate smoothly with minimal resistance.

PEEK (Polyether Ether Ketone) is a high-strength thermoplastic that withstands extreme heat while maintaining excellent structural integrity.

UHMWPE (Ultra-High-Molecular-Weight Polyethylene): Suitable for wear-heavy applications.

Choosing the Right Spring Energized Seal

When selecting a seal, consider the following:

- Operating temperature and pressure

- Type of fluid or media

- Speed and motion type (rotary, reciprocating, static)

- Regulatory compliance (FDA, USP, etc.)

Working with a reliable mechanical seal manufacturer ensures your seals are engineered precisely for your application.

Conclusion

Spring-energized seals are an essential component in advanced sealing technology. Their ability to perform under extreme conditions makes them indispensable for high-performance industrial systems. Whether you’re working with high-pressure valves, rotating equipment, or critical fluid systems, spring-energized seals offer reliability, durability, and peace of mind.