Posted At: May 09, 2025 - 1,249 Views

The Evolution of Mechanical Seals: Past, Present, and Future

Mechanical seals have been pivotal in ensuring leak-free operations in various industries, from chemical processing to water treatment. Their evolution reflects the technological advancements and the ever-growing demand for efficiency and reliability. Let's delve into the history, current state, and future prospects of mechanical seals.

The Origins: A Glimpse into the Past

The concept of sealing dates back to ancient civilizations, where materials like clay were used to prevent fluid leakage in pottery and irrigation systems. However, the modern mechanical seal, as we know it, began its journey in the early 20th century.

In 1905, George J. Cooke patented the first mechanical seal, known as the "Cooke Seal." This innovation marked a significant shift from traditional packing methods, offering a more efficient solution for preventing leaks in rotating equipment. The Cooke Seal was initially used in refrigeration compressors, setting the stage for broader applications in various industries.

By the late 1920s, the Cameron Division of Ingersoll-Rand introduced mechanical seals in centrifugal pipeline pumps, marking their commercial success in large-scale operations. The 1930s and 1940s saw further advancements, including the introduction of carbon-graphite as a seal face material and the development of O-rings, enhancing the sealing capabilities and durability of mechanical seals.

Present-Day Advancements: Meeting Modern Demands

Today's mechanical seals are the result of decades of research, innovation, and adaptation to the evolving needs of industries. Several key developments have shaped their current state:

1. Advanced Materials and Coatings

Modern mechanical seals utilize materials like silicon carbide, tungsten carbide, and advanced ceramics, offering superior resistance to wear, corrosion, and extreme temperatures. Coatings such as diamond-like carbon (DLC) further enhance durability and performance.

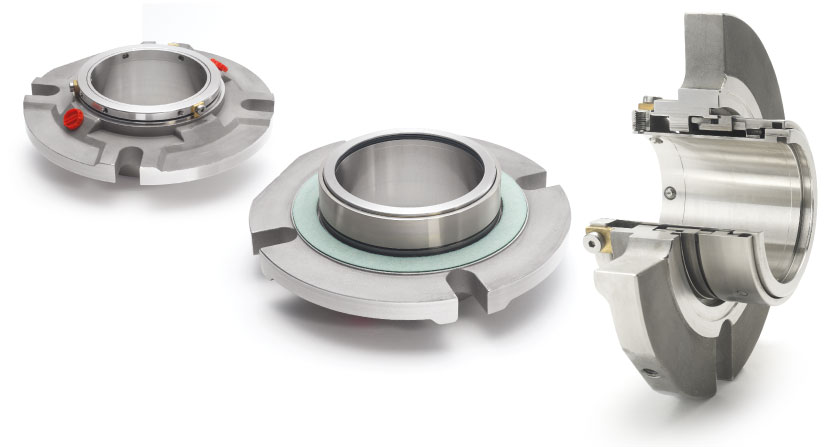

2. Cartridge Seals

Introduced in the mid-20th century, cartridge seals revolutionized installation and maintenance processes. These pre-assembled units reduce installation errors, minimize downtime, and ensure consistent performance across applications.

3. Compliance with Industry Standards

Organizations like the American Petroleum Institute (API) have established standards (e.g., API 682) to ensure the reliability and safety of mechanical seals in critical applications. These standards guide manufacturers and users in selecting and maintaining appropriate sealing solutions.

4. Environmental Considerations

With increasing environmental regulations, mechanical seals have been designed to minimize emissions and prevent hazardous leaks. Double seals and containment systems are now common in applications involving toxic or volatile substances.

The Future: Embracing Innovation

The future of mechanical seals is poised to be shaped by technological advancements and a focus on sustainability. Here are some trends and innovations to watch:

1. Smart Seals and IoT Integration

The integration of sensors and Internet of Things (IoT) technology enables real-time monitoring of seal performance. These "smart seals" can detect wear, temperature changes, and potential failures, allowing for predictive maintenance and reducing unexpected downtime.

2. Sustainable Materials

As industries strive for sustainability, the development of eco-friendly seal materials is gaining momentum. Research is focused on biodegradable and recyclable materials that maintain performance while reducing environmental impact.

3. Additive Manufacturing

3D printing and additive manufacturing techniques are being explored to produce customized seal components with complex geometries. This approach allows for rapid prototyping and tailored solutions for specific applications.

4. Enhanced Design and Simulation Tools

Advanced computational tools enable engineers to simulate seal performance under various conditions, leading to optimized designs that offer improved reliability and efficiency.

Conclusion

The journey of mechanical seals from rudimentary clay applications to sophisticated, smart sealing solutions underscores their critical role in modern industry. As technology continues to evolve, mechanical seals will undoubtedly adapt, offering enhanced performance, sustainability, and integration with digital systems. Staying abreast of these developments is essential for industries aiming to maintain efficient and leak-free operations.