Posted At: May 26, 2025 - 2,077 Views

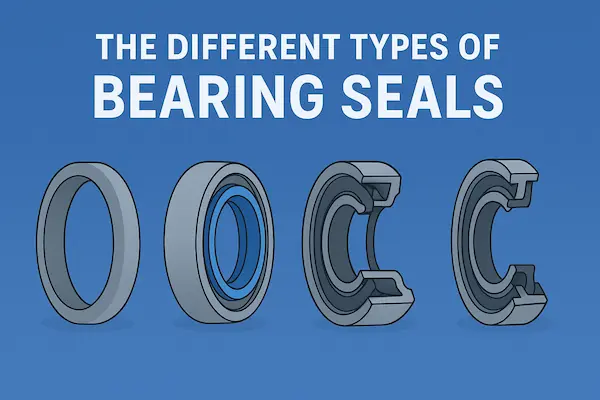

The Different Types of Bearing Seals

Introduction

Whether in pumps, motors, gearboxes or conveyors, bearings depend on effective sealing to perform reliably. Choosing the right bearing seal types means better protection, less downtime and longer equipment life. In this guide, we’ll unpack what bearing seals are, explore various types, outline their functions and show where each is best applied. With clear explanations and industrial examples, you’ll be equipped to select the correct bearing seals for your system.

What Are Bearing Seals?

A bearing seal is a component installed around a bearing or bearing housing to prevent contamination ingress (dust, moisture, debris) and retain lubricant in the bearing chamber. Without proper sealing, even high quality bearings can suffer in performance and life.

Seals help turn standard bearings into “seal bearing” configurations — ready for harsher environments and higher reliability.

Why Seal Selection Is Critical

The wrong seal type or material can result in:

Lubricant loss → increased friction & heat

Contaminant ingress → accelerated wear or corrosion

Temperature build‐up → premature failure

Unscheduled maintenance and downtime

Using the correct bearing seal types aligned to your operating environment and loads ensures you get the most from your sealed bearings.

Common Bearing Seal Types

Here are the major bearing seal types you’ll find in industrial applications:

Contact Seals

These seals make physical contact with a track or ring of the bearing. Because of the contact, they offer high sealing efficiency.

Typical uses: moderate to low speed, abrasive or wet environments.

Pros: strong contaminant exclusion, good lubricant retention.

Cons: slight additional friction, potential heat rise.

Non-Contact Seals

In this configuration the seal does not physically touch the bearing race. Rather, there’s a small gap or labyrinth to prevent ingress.

Typical uses: high speed, cleaner environments.

Pros: less friction, better for speed.

Cons: slightly less protection against fine contamination.

Labyrinth Seals

A subset of non-contact seals, labyrinth seals use a tortuous path (multiple grooves or chambers) to block contaminants without direct contact.

Typical uses: compressors, large rotating machinery, turbine shafts.

Pros: very reliable under heavy duty use, no frictional contact.

Cons: requires precise design/installation.

Shielded Bearings (Metal Shields)

Often referred to as “sealed bearings” in general terms, these bearings include integrated shields or covers (e.g., metal plates) to block larger contaminants, while still allowing lubrication to remain.

Typical uses: motors, fans, general industrial equipment.

Pros: low cost, easy to install.

Cons: not as strong as full contact seals in harsh environments.

Sealed Bearings (Factory Sealed)

These are bearings that arrive pre‐lubricated and already fitted with a seal or shield. They’re ready to install and often maintenance‐free in moderate duty applications.

Typical uses: automotive assemblies, smaller machines, general industrial use.

Pros: minimal maintenance, quick installation.

Cons: limited options for re‐lubrication or extreme environments.

Materials & Design Considerations for Bearing Seals

When selecting a seal type, consider the materials and design features:

Elastomer compounds (e.g., NBR, FKM) vs. metal/rubber combinations

Temperature & chemical exposure: ensure compatibility

Bearing speed & friction: non‐contact seals or labyrinth for higher RPM

Contamination level & environment: heavy dust/water → contact or labyrinth seal

Lubrication type & maintenance schedule: sealed bearings vs re-lubricable units

Applications & Industry Use-Cases

Below are some typical application scenarios for different bearing seal types:

Pumps & compressors → often use labyrinth seals or contact seals because of harsh fluid and solid contamination.

Electric motors and fans → shielded or sealed bearings are common given moderate environments and desire for low maintenance.

Gearboxes and heavy industrial drives → may require contact seals with backup rings to handle heavy loads and contamination.

Automotive and small machinery → sealed bearings (pre‐lubed) offer quick installation and minimal service.

How to Choose the Right Seal for Your Bearing

To select the optimal bearing seal type, follow these steps:

Define the environment (dust, water, chemicals, temperature).

Determine the speed and load of the bearing system.

Identify maintenance preferences (frequent vs minimal service).

Match the seal material to the lubricant and fluid compatibility.

Choose a design (contact, non-contact, labyrinth) that suits the operating conditions.

Consider also the bearing type and how the seal integrates into the system (seal bearing or standard bearing + external seal).

Conclusion

Understanding bearing seal types is more than just picking a product — it’s about aligning sealing design with your environment, loads and maintenance strategy. Whether you choose a contact seal, non-contact seal, labyrinth solution or factory sealed bearing, the right choice will reduce contamination ingress, improve lubricant retention and extend equipment life.

At QM Seals, our engineered sealing solutions and sealed bearings help you optimise performance, reduce downtime and keep your machines running at peak efficiency.

Frequently Asked Questions

1. What exactly is a “seal bearing”?

A "seal bearing" refers to a bearing assembly that includes a built-in seal or shield to prevent contamination and/or retain lubricant.

2. Can I convert a standard bearing into a sealed bearing?

Yes, by adding appropriate seals or shields you can protect a standard bearing — though factory sealed bearings may offer better performance in many cases.

3. How big a difference does the wrong bearing seal type make?

A mismatched seal type can dramatically shorten bearing life due to contamination ingress or lubricant loss — increasing maintenance and downtime costs.

4. Are sealed bearings always maintenance-free?

Not always. Some sealed bearings are pre-lubricated and maintenance‐free in typical conditions, but in harsh environments even sealed bearings may need inspection or replacement.

5. Does the material of the seal matter as much as the type?

Yes — material compatibility with lubricant, environment (temperature, chemicals) and speed is critical. The best seal type poorly matched with material will still underperform.