Posted At: Jul 14, 2025 - 1,654 Views

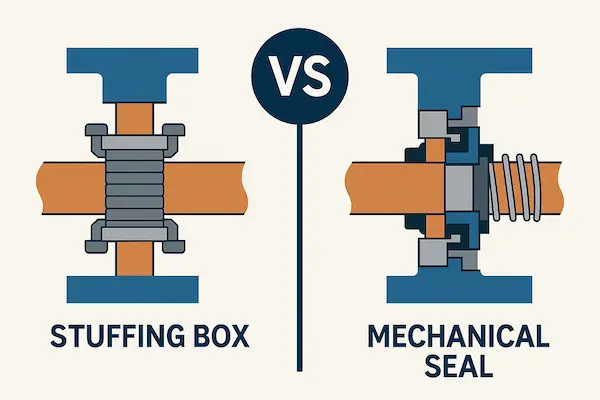

Stuffing Box vs Mechanical Seal: What’s Best for Your Pumps?

Introduction

Choosing the right sealing solution for your pumps is crucial for performance, longevity, and safety. At QMSeals, we specialize in both stuffing boxes and mechanical seals, giving you the flexibility to select the best option for your specific application.

But how do you know which one is better suited for your system? In this blog, we’ll break down the differences to help you make an informed choice.

What Is a Stuffing Box?

A stuffing box is a traditional sealing method that uses compressed packing material—typically braided graphite, PTFE, or flax—to create a seal around the rotating pump shaft.

✔️ Advantages:

Cost-effective: Lower upfront investment

Easy maintenance: Simple to adjust or repack

Rugged: Handles abrasive and dirty fluids well

❌ Disadvantages:

Leaks by design: Requires constant dripping for lubrication and cooling

Frequent maintenance: Requires periodic tightening or repacking

Energy loss: Increased friction can reduce efficiency

What Is a Mechanical Seal?

A mechanical seal uses two flat surfaces—one stationary, one rotating—pressed together to form a tight seal. These seals are supported by O-rings, springs, and other components for enhanced performance.

✔️ Advantages:

Minimal leakage: Almost leak-free, better for environmental compliance

Lower maintenance: Designed for long-term operation

Efficient: Reduces friction and energy loss

❌ Disadvantages:

Higher initial cost: More complex design and precision parts

Requires proper installation: Sensitive to misalignment or poor handling

Not ideal for dirty or abrasive fluids without special design

Stuffing Box vs Mechanical Seal: Direct Comparison

| Feature | Stuffing Box | Mechanical Seal |

|---|---|---|

| Leakage Control | Allows controlled leakage | Minimal or no leakage |

| Maintenance | Frequent adjustment/repacking | Infrequent, requires skill to install |

| Initial Cost | Low | High |

| Long-Term Cost | Higher due to maintenance/downtime | Lower with proper use |

| Fluid Compatibility | Excellent for abrasive fluids | Better for clean, high-value fluids |

| Efficiency | Slightly reduced by friction | High efficiency due to tight seal |

When to Use a Stuffing Box

Choose a stuffing box if:

Your system handles abrasive, slurry, or dirty fluids

You operate in a low-cost, high-maintenance environment

Occasional leakage is acceptable

You're looking for a simple, rugged solution

When to Use a Mechanical Seal

Choose a mechanical seal if:

You need to handle toxic, flammable, or expensive fluids

Leak-free operation is essential for safety or compliance

Your system runs at high pressure or speed

You're focused on long-term savings and reduced downtime

QMSeals: Your Sealing Partner

Whether you need a stuffing box for a robust slurry application or a mechanical seal for clean, leak-proof operations—QMSeals has the right solution. Our products are designed to deliver high performance, reliability, and cost efficiency in real-world pump systems.

We can guide you through:

Product selection based on your application

Custom sealing solutions

On-site consultation and support

Conclusion

There is no one-size-fits-all answer when it comes to pump seals. The choice between a stuffing box and a mechanical seal depends on your operational needs, fluid characteristics, and budget priorities.

Need help deciding? Contact QMSeals today to speak with our seal specialists.