Posted At: Jan 10, 2026 - 493 Views

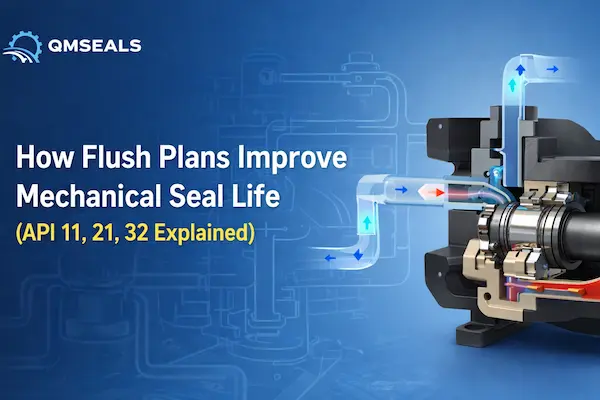

How Flush Plans Improve Mechanical Seal Life

Mechanical seal reliability plays a critical role in the overall performance and uptime of pumps used in process industries. One of the most effective yet often misunderstood aspects of seal reliability is the mechanical seal flush plan. Properly designed flush plans help control temperature, pressure, lubrication, and contamination around the seal faces—directly extending seal life and preventing premature failures.

In this blog, we will explain how flush plans improve mechanical seal life, explore commonly used API flush plans, and help you understand when and why each plan is required.

What Is a Mechanical Seal Flush Plan?

A mechanical seal flush plan refers to an engineered method of introducing, circulating, or removing fluid around the mechanical seal to create a stable sealing environment. The flush fluid may be the pumped product itself or an external fluid, depending on the application.

Flush plans are designed to:

- Remove heat generated at seal faces

- Prevent dry running

- Flush away solids or contaminants

- Maintain proper lubrication

- Control pressure around the seal chamber

Without an effective flush plan, even the highest-quality mechanical seal can fail prematurely.

Why Flush Plans Are Critical for Mechanical Seal Life

Mechanical seals operate under extreme conditions—high temperature, pressure, speed, and chemical exposure. Flush plans improve seal life by addressing these challenges systematically.

1. Temperature Control

Seal faces generate heat due to friction. Flush plans help dissipate this heat, preventing:

- Seal face distortion

- Elastomer hardening

- Thermal cracking

2. Improved Lubrication

A clean and consistent fluid film between seal faces reduces friction and wear. Proper flushing ensures continuous lubrication, even during start-up and shutdown.

3. Contamination Removal

In applications involving slurry, chemicals, or dirty fluids, flush plans remove solids that could scratch or damage seal faces.

4. Pressure Stabilization

Flush systems help maintain stable pressure at the seal chamber, reducing flashing and vaporization.

5. Extended Seal & Equipment Life

By maintaining ideal operating conditions, flush plans reduce unplanned downtime, maintenance costs, and seal replacement frequency.

Common API Mechanical Seal Flush Plans Explained

The American Petroleum Institute (API) has standardized several flush plans widely used in industrial pumping systems. Below are the most commonly used ones.

API Plan 11 – Internal Recirculation

API Plan 11 is one of the most widely used mechanical seal flush plans.

How It Works:

Fluid is taken from the pump discharge

Routed through an orifice

Directed into the seal chamber

Key Benefits:

Simple and cost-effective

Uses process fluid (no external supply)

Provides cooling and lubrication

Limitations:

Not suitable for dirty or abrasive fluids

Heat removal capability is limited

Typical Applications:

Clean liquids

General-purpose centrifugal pumps

API Plan 21 – Cooled Recirculation

API Plan 21 is similar to Plan 11 but includes a cooler.

How It Works:

Discharge fluid passes through a cooler

Cooled fluid enters the seal chamber

Key Benefits:

Better temperature control than Plan 11

Reduces thermal stress on seal faces

Limitations:

Requires additional piping and cooler

Still unsuitable for dirty fluids

Typical Applications:

Hot hydrocarbons

High-temperature oil pumps

API Plan 32 – External Flush

API Plan 32 uses an external clean fluid to flush the seal.

How It Works:

Clean external fluid is injected into the seal chamber

Flush pressure is maintained higher than seal chamber pressure

Key Benefits:

- Prevents contamination

- Excellent for corrosive, slurry, or dirty fluids

- Provides superior lubrication

Limitations:

- Requires external fluid source

- Higher operating cost

Typical Applications:

- Chemical pumps

- Slurry pumps

- Abrasive or corrosive services

How to Select the Right Flush Plan for Your Mechanical Seal

Selecting the correct flush plan depends on several operating factors:

1. Pumped Fluid Characteristics

- Clean or dirty

- Abrasive or corrosive

- Viscosity and volatility

2. Operating Temperature & Pressure

High-temperature or high-pressure applications typically require cooled or external flush plans.

3. Seal Arrangement

Single mechanical seals often use Plans 11 or 21

Double mechanical seals commonly use Plan 32 or barrier fluid systems

4. Industry & Application

Chemical and pharma industries favor external flush plans

Oil & gas applications often use API-compliant flush systems

Common Problems Caused by Improper Flush Plans

An incorrect or poorly maintained flush plan can lead to:

- Excessive seal leakage

- Seal face wear and scoring

- Heat buildup and thermal cracking

- Reduced MTBF (Mean Time Between Failures)

Proper flush plan design and maintenance are just as important as selecting the right mechanical seal.

Best Practices to Maximize Mechanical Seal Life Using Flush Plans

- Ensure correct flush pressure and flow rate

- Use clean and compatible flush fluids

- Regularly inspect orifices, coolers, and piping

- Match flush plan to seal design and process conditions

- Work with experienced mechanical seal manufacturers

Conclusion

Mechanical seal flush plans play a vital role in controlling heat, contamination, and lubrication at the seal interface. By selecting and maintaining the correct flush plan—such as API Plans 11, 21, or 32—you can significantly improve mechanical seal life, reduce failures, and enhance overall pump performance.

For critical applications, investing in the right flush plan is not an option—it is a necessity.

Frequently Asked Questions:

What is the purpose of a mechanical seal flush plan?

A flush plan controls temperature, lubrication, and cleanliness around the seal faces to extend seal life.

Which flush plan is best for dirty fluids?

API Plan 32 is ideal for dirty, abrasive, or corrosive fluids.

Can flush plans reduce seal leakage?

Yes, proper flush plans stabilize seal conditions and significantly reduce leakage.

Are flush plans mandatory for mechanical seals?

While not mandatory for all applications, flush plans are critical in high-temperature, high-pressure, or contaminated services.