Mechanical seal supplier Thailand

We manufacture and supply mechanical seals for a range of uses, such as pusher, non-pusher, cartridge, agitator, bellow, and engineered seals. Thailand is experiencing significant growth, particularly in manufacturing industries such as paper and pulp, automotive, and food and beverage, etc. Our company has been providing top-notch mechanical seals to these sectors at a reasonable cost, aiding them in expanding their operations. Our seals have been widely used by different industries across Thailand, and we have built long-term relationships with our clients.

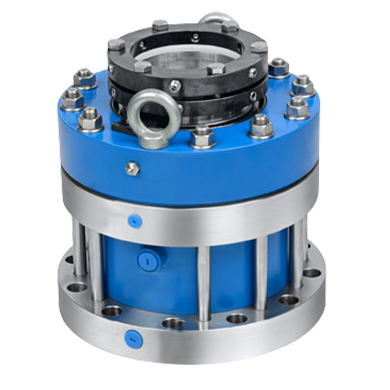

Agitator Mechanical seal

What choices are available for agitator seals in a Glass-lined reactor?

When using glass-lined reactors, it's crucial to consider the materials used for the seal's different components. Some utilize metal and elastomers that aren't suitable for the process environment, defeating the purpose of using glass-lined equipment. But don't worry, there are various designs available that use appropriate materials for applications involving glass-lined equipment.

“Wet Seals”

Wet seals are commonly used in high-pressure and high-temperature applications to prevent leakage. They use a liquid barrier fluid for lubrication and to contain the contents of the reactor. A seal pot, also known as a lubricator, is used as a reservoir for the fluid, which circulates through the seal naturally. In some cases, a pump is used to force the circulation of the sealing fluid. Wet seals are necessary for operating pressures exceeding 150 PSIG or when operating temperatures are above 350°F.

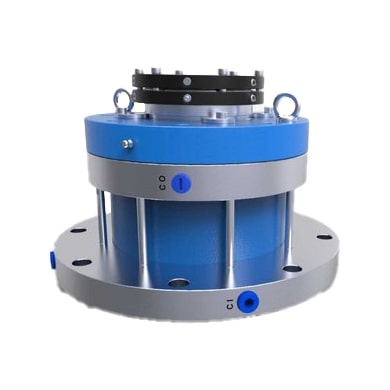

“Dry Seals”

- Dry seals are so named because they use Nitrogen gas as a barrier instead of liquid, which is used in wet seals. This helps eliminate contamination from fluid leakage.

- Dry seals are built with special carbon grades for seal faces and machined to tight tolerances to minimize wear.

- Some designs even incorporate a "lift off" feature to further reduce wear and avoid contact during operation.

- However, there is always some degree of wear, especially during start up and shutdown of the agitator that cannot be eliminated completely.

High-Purity Seals

- In certain industries, particularly pharmaceuticals, it's vital to avoid any contamination of the batch contents. However, the particles produced by the seal face can pose a challenge.

- To address this, some seal designs feature a "debris well" that hangs beneath the seal in the reactor's vapour space.

- The debris well is crafted using a top-quality alloy material, ensuring its capability to endure the chemical surroundings within the container. Its primary objective is to trap a significant number of carbon particles before they mix with the reactor contents.

- It is necessary to periodically clean out this debris well between batches.