Posted At: May 20, 2025 - 1,779 Views

Different Mechanical Seal Types for Centrifugal Pumps

What Are Mechanical Seals & Why They Matter in Pumps

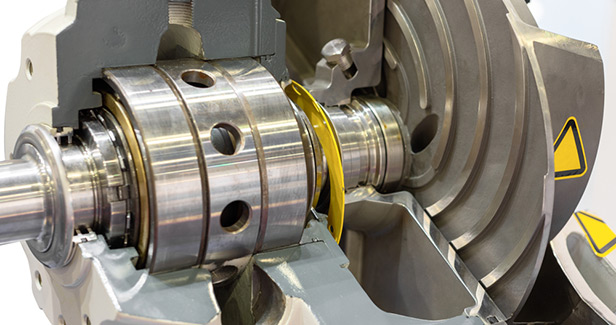

Mechanical seals are vital in centrifugal pumps, forming a tight barrier between the rotating shaft and the pump housing. These mechanical seal types prevent fluid leakage, maintain system pressure, and protect critical equipment from contamination or failure. Unlike older packing systems, mechanical seals offer better reliability, lower friction, and reduced maintenance for industrial operations.

In demanding industries — such as oil & gas, petrochemical, and heavy process plants — choosing the right mechanical seal in pump design directly affects uptime, safety, and cost.

Key Types of Mechanical Seal (Pump Seal Types)

Here are the most common types of mechanical seal used in centrifugal pumps, along with their key features:

Single Mechanical Seals

Use a single pair of seal faces (rotating and stationary).

Ideal for clean or non-hazardous fluids under moderate pressure.

Cost-effective, but not suited for high-leak-risk or critical applications.

Double (Dual) Mechanical Seals

Consist of two sets of seal faces (inner + outer).

Provide extra protection by using a buffer or barrier fluid between the seals.

Widely used for high-pressure, aggressive, volatile, or hazardous fluids.

This seal type is especially recommended when minimizing leakage or emissions is critical.

Cartridge Mechanical Seals

Preassembled units with seal faces, hardware, sleeve, and gland.

Quick to install, reducing human error and alignment problems.

Great for maintenance-heavy or field-repair contexts.

Split Mechanical Seals

Designed in two halves so they can be installed or replaced without removing the pump casing or disconnecting shaft components.

Highly useful in large, hard-to-shut-down systems, such as split-case or pipeline pumps.

Metal Bellows (Non-Pusher) Seals

Use welded metal bellows instead of springs or elastomers to apply axial load.

Best for high-temperature or aggressive chemical services where elastomer degradation is a risk.

Very flexible and reliable over varying thermal cycles.

Balanced vs. Unbalanced Seals

Balanced Seals: Hydraulic forces at the seal faces are reduced by design, enabling them to handle higher pressures and reducing heat buildup.

Unbalanced Seals: Simpler, cheaper, and work well under moderate pressure — but not ideal for very high-pressure or high Pv (pressure-velocity) applications.

How to Choose the Right Mechanical Seal Type

Selecting the correct mechanical seal type is critical. Here are the key parameters to guide your decision:

Fluid Characteristics: Consider fluid type (corrosive, volatile, abrasive), cleanliness, and lubricity.

Operating Conditions: Know your temperature, pressure, shaft speed, and direction of shaft load.

Pump Configuration: Analyze the type of pump (split, multistage), seal chamber dimensions, and whether you need a cartridge or component seal.

Safety & Compliance: For hazardous fluids, double seals or API- 682-compliant arrangements may be needed.

Maintenance Needs: How often will you inspect or replace the seal? Split or cartridge seals can reduce maintenance downtime.

Material Compatibility: Face materials (e.g., silicon carbide, carbon, ceramic) and secondary seals (O-rings) must match your process environment.

Common Failure Modes & Prevention

Mechanical seals can fail for several reasons. Here are some typical failure modes, and how to prevent them:

Face Wear or Damage: Incorrect face material or poor lubrication can lead to rapid wear. → Use seal faces matched to your fluid and load conditions.

Seal Misalignment: Bad installation or shaft deflection causes uneven contact. → Use cartridge seals or correct alignment during assembly.

Thermal Stress: High temperature cycles can degrade elastomer or metal components. → Choose bellows seals or balanced designs.

Leakage or Emissions: In volatile or toxic fluid services, a single seal might not be enough. → Use a double seal with a buffer or barrier system.

Why Go With QMSeals for Mechanical Seals

Application-Specific Design: We tailor mechanical seal types to your fluid, pressure, and temperature.

High-Quality Materials: We use durable seal face materials (e.g., silicon carbide, tungsten carbide, carbon), and robust secondary elements (O-rings, bellows) to match your process.

Seal Support Systems: We provide Plan 53A/B, Plan 54, and other seal support systems for double seals to manage buffer fluids, cooling, and reliability.

Low Risk, High Reliability: Our cartridge and split seal options minimize installation risk and downtime.

Industrial Expertise: With deep experience in oil & gas, petrochemical, chemical, and power sectors, we can guide you to the right seal strategy.

Flexaseal, a leading seal-engineering company, outlines several mechanical seal types similar to those offered by QMSeals: balanced vs unbalanced, pusher vs non-pusher, conventional vs cartridge seals.

At QMSeals, we combine these proven seal-type architectures with our own expertise in material selection and custom seal system design. This ensures optimized performance, longer seal life, and lower total cost.

Conclusion

Understanding mechanical seal types is essential for anyone working with centrifugal pumps. The correct types of mechanical seals can dramatically improve efficiency, reduce risk, and extend the life of rotating equipment. At QMSeals, we offer advanced, reliable, and customized pump seal types that are engineered to match your industrial needs. Whether you need balanced, pusher, cartridge, or double seals — we have the right solution.

→ Get in touch with QMSeals for a seal consultation. Let our engineers help you choose the best mechanical seal type for your pump application.