Posted At: Apr 18, 2025 - 1,085 Views

Difference Between Component vs. Cartridge Mechanical Seals

Mechanical seals play a vital role in ensuring leak-free performance in pumps and rotating equipment. Among the most commonly used types are component seals and cartridge seals. Choosing the right one is essential for maximizing efficiency, minimizing downtime, and maintaining the integrity of your system. In this blog, we’ll break down the key differences between component mechanical seals and cartridge mechanical seals, so you can make an informed decision for your application.

What Are Mechanical Seals?

Before diving into the differences, let’s briefly understand what mechanical seals are. Mechanical seals are devices used to prevent fluid leakage where a rotating shaft passes through a stationary pump housing. They are designed to contain the process fluid within the pump and prevent external contaminants from entering the system.

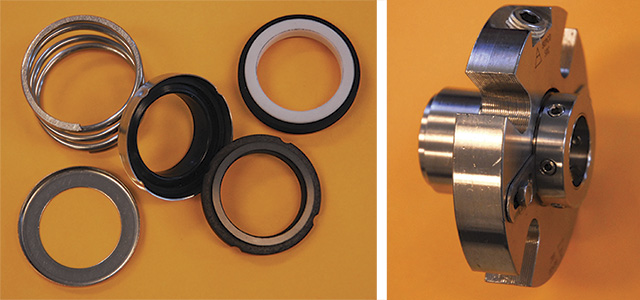

What is a Component Mechanical Seal?

Component seals are made up of multiple separate parts—typically the rotating and stationary elements, secondary seals, and gland plates—that need to be assembled directly onto the pump shaft during installation.

Key Features of Component Seals:

- Require precise installation and alignment

- Cost-effective option for many standard applications

- Allow flexibility in customizing materials for each part

When to Use Component Seals:

Component seals are ideal when you have trained maintenance staff and want more flexibility in choosing and replacing parts. They're often used in systems where seal cost and accessibility are key concerns.

What is a Cartridge Mechanical Seal?

Cartridge seals are pre-assembled, factory-tested sealing units that combine all seal components into a single cartridge. They’re designed to be installed as one complete unit, which reduces the chances of installation errors.

Key Features of Cartridge Seals:

- Easy to install with minimal training

- Reduces downtime and maintenance complexity

- Minimizes human error during setup

When to Use Cartridge Seals:

Cartridge seals are ideal for critical applications where reliability and speed of maintenance are important. They’re commonly used in industries like pharmaceuticals, food processing, oil and gas, and chemical manufacturing.

Component vs. Cartridge Mechanical Seals:

Feature | Component Seal | Cartridge Seal |

|---|---|---|

Installation | Manual and skill-based | Quick and simple |

Maintenance | Requires disassembly and reassembly | Pre-assembled unit; easy to replace |

Cost | Lower initial cost | Higher upfront cost |

Downtime | Can be longer | Minimal |

Error Margin | High risk of misalignment | Factory-aligned, lower error |

Flexibility | High – can mix and match parts | Less flexible |

Which Seal Is Right for You?

Choosing between component vs. cartridge mechanical seals depends on a few key factors:

Maintenance expertise – Do you have skilled technicians who can assemble seals correctly?

Criticality of application – Is downtime expensive or risky for your operation?

Budget – Are you prioritizing upfront cost or long-term reliability?

If you’re looking for cost efficiency and have skilled staff, a component mechanical seal might be the better choice. However, if you want reliability, speed, and minimal risk, cartridge mechanical seals are a smart investment.

Advantages of Cartridge Seals:

Easy to install – ideal for quick replacements

Reduced chance of installation errors

Long-term cost savings due to lower maintenance time

Advantages of Component Seals:

Lower initial cost

Customization flexibility

Ideal for less demanding applications

Conclusion

Understanding the difference between component and cartridge mechanical seals can make a huge impact on your equipment’s performance and maintenance costs. Each type has its own advantages depending on your operational needs.

If you’re unsure which seal type is right for your pump system, Quality Mechanical Seals (QMSeals) can help you make the best decision. With expert advice and a wide range of high-quality mechanical seals, we’re here to support your business.

Frequently Asked Questions

Are cartridge seals better than component seals?

Cartridge seals are better for ease of installation and reducing errors, but component seals are more budget-friendly and customizable.

Can I replace a component seal with a cartridge seal?

Yes, in many cases, cartridge seals can be retrofitted if the pump design allows it.

Which industries use cartridge mechanical seals?

Pharmaceuticals, oil and gas, food and beverage, and chemical processing commonly use cartridge seals.

How long does a mechanical seal typically last?

With proper maintenance, a mechanical seal can last anywhere from 1 to 5 years, depending on the application.

What is the biggest reason for mechanical seal failure?

Improper installation is one of the leading causes, which is why cartridge seals are often recommended.